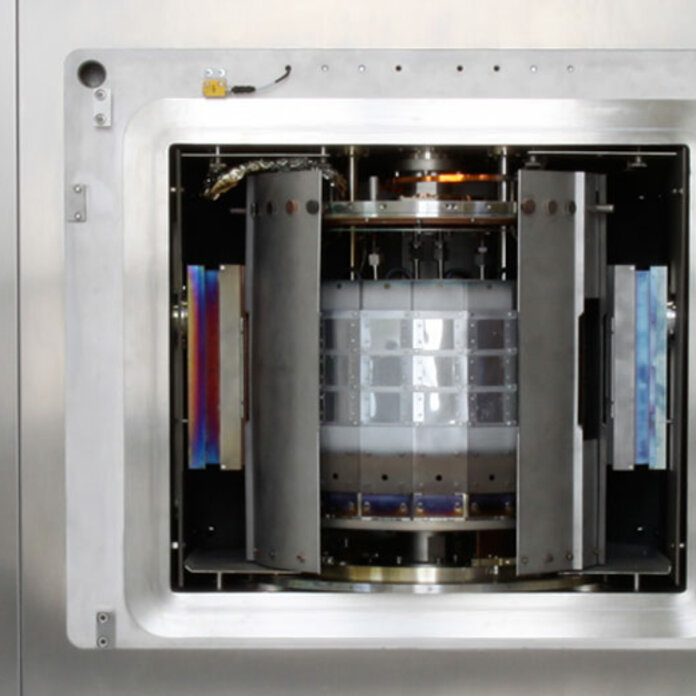

Magnetron Sputtering Systems with Special Drum Concept for Small Substrates

FHR.BOXX Product Range

- Single chamber systems

- Systems with lock chamber

- With and without sub-rotation

- With clean room connection

Thin film coating systems for coating plates, disks, wafers, pins, needles for R&D and production.

- Microelectronics

- Electronics

- Printed circuit boards

- Sensors

- Display

- OLED

- Thin film solar cells

- Thin film batteries

- and much more

Single-chamber sputtering systems are a cost-effective solution for vacuum coating in small series production. The sputtering systems in our FHR.Boxx product range – also known as “Box Coaters” – do not require an airlock chamber. The substrate is loaded directly with the process chamber open.

The substrate carrier in the recipient is a rotating drum, which can also be used to heat the mostly small substrates. By rotating the drum during the vacuum process, the substrates to be coated can be moved past several process stations.

By installing a sub-rotation, it is even possible to coat 3D substrates such as spectacle lenses or lamps. On balance, a good layer thickness homogeneity is achieved. Substrate pre-treatment, e.g. by means of plasma etching, is also possible.

The following technologies can be implemented on our box / drum coating systems according to the specific requirements of the individual customer.

- Magnetron sputtering

- Plasma etching (PE)

- Heat treatment

With the systems in FHR.Boxx product family, our customers acquire high-quality coating machines that combine a wide range of features and benefits.

- Several coating and pre-cleaning stations

- Production of layer systems possible

- Possibility of a loading lock

- Substrate sub-rotation

- Substrate heating

- Minimization of particles and “flitter” due to vertical design

- Easy servicing due to good availability of components

- Attractive investment and operating costs

- Use of FHR’s own sputtering technology

Your Contact Person

Do you have any questions?

Would you like to know more about our FHR.Boxx product range? Our expert, Peter Stiewe, will be happy to help you. Get in touch with us.

Vacuum Coating Systems

OTHER PRODUCT SERIES

Product Enquiry

You would like to learn more about our product? We are at your disposal. Contact us today to request detailed information, ask questions or receive individual advice.

Your interest is important to us, and we look forward to hearing from you!