Flexible CIGS Solar Cells – R&D

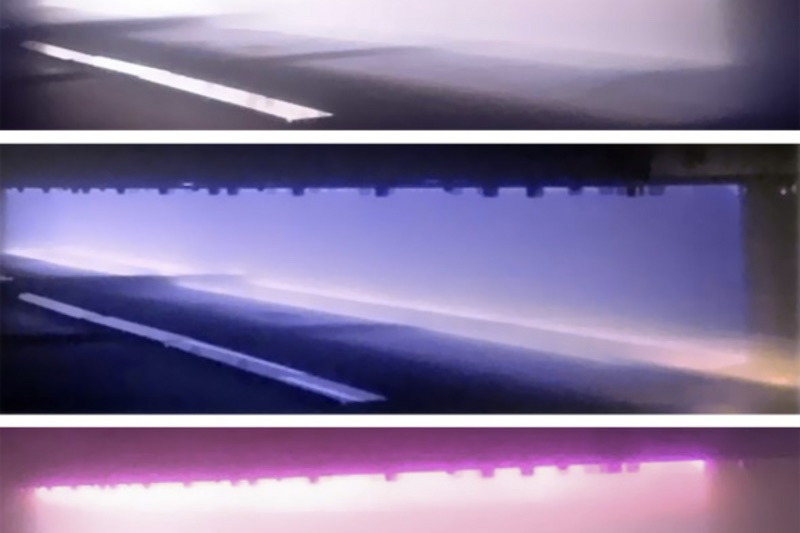

Roll-to-roll laboratory system for the deposition of CIGS solar cells on films

APPLICATION

Solar energy is not only free, but – with cetain time restrictions – also available everywhere. Where prolonged disconnection from the power grid is unavoidable, solar cells are cheaper and lighter than carrying energy in the form of batteries or fuel, e.g. for stationary systems in remote locations, in mobile outdoor applications or in satellites. For installation on roofs that do not have the structural characteristics for heavy panels, or even tarpaulins, the solar cell must also be very light.

REQUIREMENTS FOR THE SYSTEM

The two pilot systems will coat film with solar cells using a roll-to-roll process. One system sputters the transparent and metallic electrodes, while the other applies the CIGS absorber layers by means of thermal evaporation. The systems are used for process development and the production of samples, but not yet for mass production. The systems must, therefore, be large enough to reproduce realistic process conditions in production; however, due to the cost of the system, film and coating material, they should not be any larger. As pilot systems, they must also be particularly flexible, as the process details – and perhaps even the layer structure – can still change.

- High efficiency of the solar cell

- Low weight

SOLVING THE REQUIREMENTS

The two roll-to-roll systems have already been built in a similar form for a number of other R&D projects and coat film 300 mm wide and up to 500 m long – typical values for a pilot system. In terms of the winding unit, both systems are almost identical: Unwinding, winding and spreading of the film take place in the upper part of the systems, while the process units – sputter sources or evaporators – are arranged around the process drum in the system’s lower part. The process drum can be tempered, as the substrate temperature has a decisive influence on layer growth. The full-surface front door and the two large side doors allow easy access to all parts of the system. Additional flanges allow components to be retrofitted.

THE SPECIAL FEATURES OF THIS COATING SYSTEM

- Flexible system design for R&D in the roll-to-roll process

- Designed as a sputter and evaporator system

- Integration of in-situ measurement technology, e.g. XRD

- Process roller water-cooled or heatable up to well over 200 °C

- Automated coating with full control over all winding and process parameters

Your Contact Person

Do you have any questions?

Would you like to know more about our FHR.Roll product range? Our expert, Sven Häberlein, will be happy to help you. Get in touch with us.