COATINGS IN THE SEMICONDUCTOR AND ELECTRONICS INDUSTRY

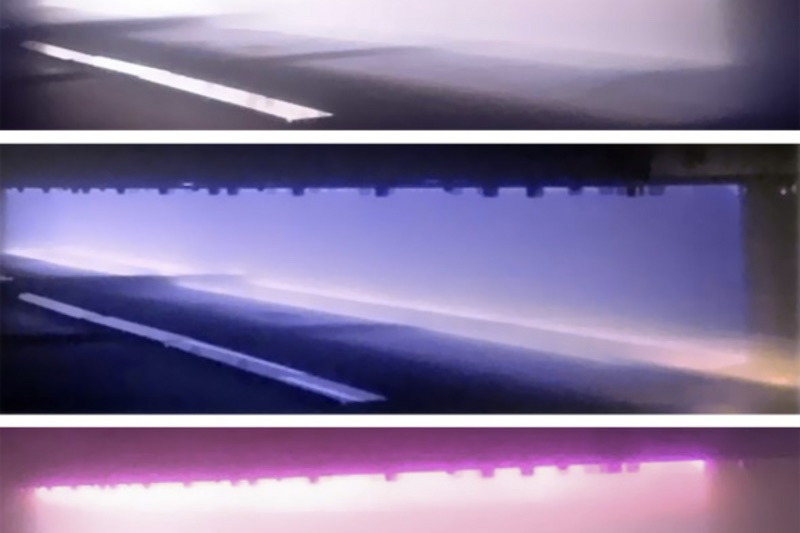

Thermal vapor deposition is one of the PVD coating processes. This process is used to apply functional coatings of condensed particle vapor. This technology is impressive thanks to the possibility of very high coating rates. Another outstanding feature is the bandwidth of the process: Different materials can be combined by means of co-evaporation, in order to create a customized material mix for specific application requirements. This makes thermal vapor deposition a key technology for advanced coating solutions.

Find out more about this reliable and precise technique in thin film technology.

How It All Works

HOW DOES THERMAL VAPOR DEPOSITION WORK?

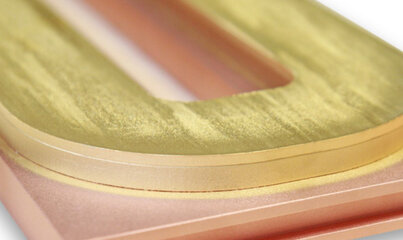

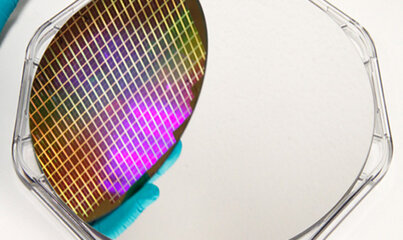

Thermal vapor deposition can be used to apply thin coatings of metals – such as copper, silver or gold, as well as other materials like silicon dioxide or indium tin oxide – to a surface. This method is also used to produce organic semiconductors or special solar cells, such as CIGS solar cells. In CIGS solar cells, copper, indium, gallium, and selenium are applied together. In organic solar cells, monomers are vapor-deposited. FHR is a top supplier of coating systems in this professional discipline.

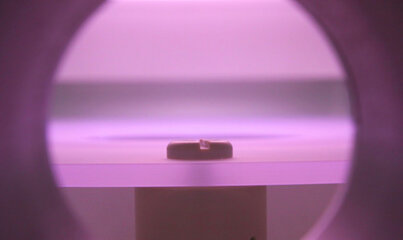

Thermal vapor deposition is one of the techniques that falls under the umbrella of PVD (Physical Vapor Deposition). The material to be applied is heated until it vaporizes. This vapor then settles as a thin film on the surface.

Thermal vapor deposition takes place in an almost airless room. The coating process is improved by adding oxygen, for example. This step is particularly effective when applying indium tin oxide coatings, which subsequently increases the process quality and efficiency.

One advantage of thermal vapor deposition is that thin coatings can be applied relatively quickly. The exact speed depends on the material and the desired properties of the coating. In order to get the best out of this method, FHR offers various vacuum coating systems that are specially designed for different materials and requirements.

Thermal vapor deposition offers several key advantages over other coating techniques:

- High coating rates: The process often facilitates the faster deposition of materials when compared to other vacuum coating techniques, which can shorten production times.

- Coating purity: As thermal vapor deposition takes place in a vacuum, the coatings produced are typically of high purity and free from atmospheric impurities.

- Simplicity and cost efficiency: Thermal vapor deposition is generally less complex than some other PVD methods and requires less specialized equipment, which can lead to lower operating costs.

- Flexibility through co-evaporation: The ability to vaporize several materials simultaneously enables the production of alloys or multi-component coatings, which can be useful for specific application requirements.

- Effective adhesion: The coatings produced are often characterized by excellent adhesion to the substrate, resulting in durable and resistant coatings.

These advantages make thermal vapor deposition a versatile and powerful tool in the world of thin film technology.

Vacuum coating systems

Discover how our vacuum coating systems form the basis for high-performance coatings in numerous industries, and how our technologies can be used for your projects.

Other technologies and coating processes

FHR – The Right Partner at Your Side

Shaping the future together – with reliable and high-quality coating solutions from FHR:

- Industry-leading quality: Our vacuum coating systems are designed for maximum precision and durability.

- Customized solutions: We offer individual solutions for your coating project that meet your specific requirements.

- Innovative methods and technologies: With our many years of experience and expertise in vacuum coating, we continue to set new standards.

- Dedicated customer service: Our experienced team is always available to answer your questions and provide you with support in your projects.

Discover the diverse range of possibilities with our vacuum coating technology, and place your trust in FHR as your reliable partner for outstanding coating solutions. Please feel free to get in touch with us to find out more and realize your projects together.

Your Contact Person

Do you have any questions?

Would you like to discover more about thin film technology or receive general advice on our vacuum coating systems and our coating service? Then feel free to get in touch with us – our team of experts will be happy to answer all your questions.