Process for pre-cleaning substrates before sputtering

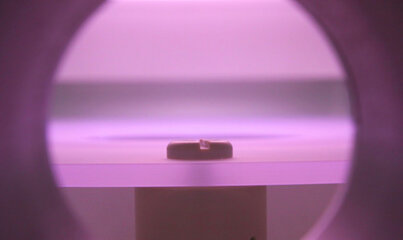

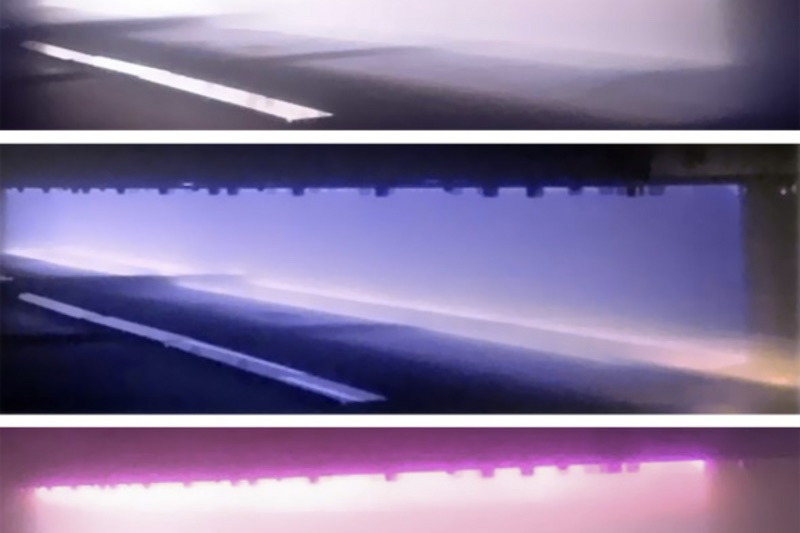

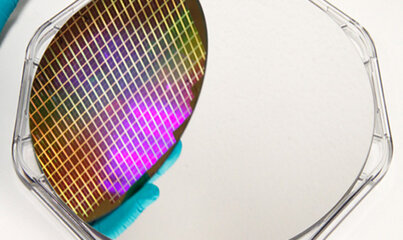

Plasma etching is a highly-developed dry etching process that is widely used in material processing, in particular, in the semiconductor industry. By using plasma, materials can be removed from a substrate with extraordinary precision. Plasma etching also serves as a method for pre-cleaning substrates by removing unwanted impurities and oxides before further process steps are performed.

Find out more about this reliable and precise technique in thin film technology.

How It All Works

What is behind the plasma etching?

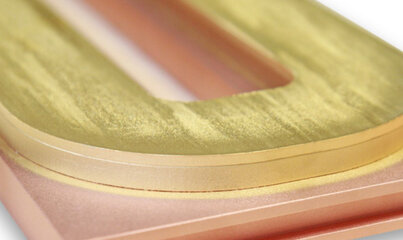

Plasma etching (also known as “plasma-assisted ion etching”) is a process in which material is removed from a surface by the impact of high-energy gas ions. Another name for this method is “sputter etching”. This process is often used at FHR Anlagenbau GmbH. It can also be used to gently clean surfaces before further sputtering begins. This ensures optimum adhesion and quality with regard to subsequent coatings or finishes. The process, therefore, combines not only etching capabilities, but also essential preparatory steps for various applications.

In plasma etching, the material is mainly removed in the direction from which the ions strike. This process is particularly useful for materials that do not react easily with standard etching gases. One disadvantage, however, is that the material is only removed at a slow rate. In addition to this point, plasma etching removes most materials equally, and does not differentiate significantly between them, making it less selective.

Plasma etching offers several advantages:

- Drying process: As plasma etching is a dry etching process, it eliminates the need for wet chemicals, thereby reducing the risk of contamination and chemical residues.

- High level of precision and reproducibility: Plasma etching enables the precise structuring and definition of the finest patterns, making it particularly suitable for applications in the semiconductor industry and nano-technology.

- Pre-cleaning of substrates: Before the actual material processing begins, plasma etching can be used to remove impurities and oxides from substrate surfaces, thus resulting in the enhanced quality and adhesion of subsequent coatings.

- Versatility: By utilizing different process gases, plasma etching can be used to etch a variety of materials, making it suitable for a wide range of applications.

These properties make plasma etching a valuable tool in modern manufacturing and material processing.

Vacuum coating systems

Discover how our vacuum coating systems form the basis for high-performance coatings in numerous industries, and how our technologies can be used for your projects.

Other technologies and coating processes

FHR – The Right Partner at Your Side

Shaping the future together – with reliable and high-quality coating solutions from FHR:

- Industry-leading quality: Our vacuum coating systems are designed for maximum precision and durability.

- Customized solutions: We offer individual solutions for your coating project that meet your specific requirements.

- Innovative methods and technologies: With our many years of experience and expertise in vacuum coating, we continue to set new standards.

- Dedicated customer service: Our experienced team is always available to answer your questions and provide you with support in your projects.

Discover the diverse range of possibilities with our vacuum coating technology, and place your trust in FHR as your reliable partner for outstanding coating solutions. Please feel free to get in touch with us to find out more and realize your projects together.

Your Contact Person

Do you have any questions?

Would you like to discover more about thin film technology or receive general advice on our vacuum coating systems and our coating service? Then feel free to get in touch with us – our team of experts will be happy to answer all your questions.